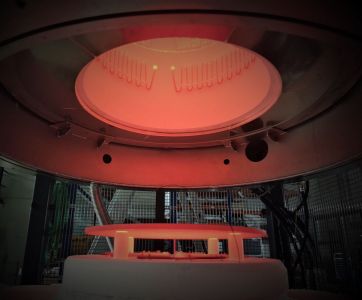

Sintering of technical ceramics (brown bodies)

Pottery kilns have been used since at least the 4th millennium BC. Since then, firing and sintering kilns have evolved due to increasing product requirements. The principle of sintering has remained the same. The temperature treatment during sintering transforms a fine-grained or coarse-grained brown body into a solid workpiece.

Process management decisive

The sintered product only acquires its final properties through heat treatment. Under vacuum or controlled atmosphere and in defined temperature ranges, properties such as hardness, strength or thermal diffusivity required for the respective technical ceramic are influenced.

Sintering furnace for your process

The sintering furnaces from IBT.Thermprocess cover these sintering processes with a high degree of flexibility. We would be happy to check whether you can also carry out the debinding process with our sintering furnaces.

YOU MIGHT ALSO BE INTERESTED IN THIS:

Products & Solutions:

Ingolf Jaeger

Head of Sales

Dipl.-Ing. Mechanical Engineering

E-Mail: i.jaeger@ibt.de

Phone.: +49 (0) 3731 1683-15